Recently

SEW-EURODRIVE interviewed one of our engineers. Read the result of the

interview below.

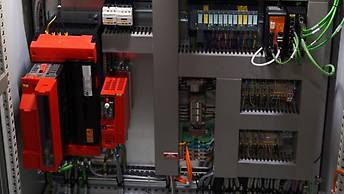

Compact, space-saving control cabinets and only two cables for communication and power supply gave this customer the possibility to quickly commission the newly delivered drives with less space. By chance, the machine supplier was aware of SEW-EURODRIVE's decentralized technologies and products. Qimarox has been using these himself for years, allowing the company to design, build, test, de-install, and deliver quickly.

Lego blocks

Berry

Jansen, a software engineer at R&D, has been working at Qimarox for 15

years and he examined the entire manufacturing process of the company, with a

special focus on standardization and making modular and reusable products. “We

want to build modularly, increasing the reusability of system components and

reducing lead times. Hence, decentralized technology is of interest to us. This

fits in with our strategy to build a system with 'Lego blocks'. The customer

wants to get the missing Lego blocks from us.” Qimarox, therefore, supplies

them with its modules. “With our broad product range, together with our

partners (OEMs and system integrators) we can reach and serve every end-user -

anywhere in the world. Because of the standardization of all our products, a

machine can always be configured quickly - customer-specific. And our partners

don't have to develop anything themselves.”

The advantages of decentralized technology

“What's in the control cabinet is now practically

always the same,” says Jansen. “Then it becomes a fixed cost, the calculation

is faster and it remains clear and simple for customers. That's not the only

advantage. Better testing is possible since the 'Lego blocks' are already

completely wired and these modules can be tested without a control cabinet.

This saves time in the start-up phase. In addition, the learning curve for

integrators is also lower, because they get a complete set. In short, they only

need to set the scope of size and weight or the transmission ratio. Also,

exchanging parts is easier."

And this is not all. In terms of size, the control

cabinet is only a quarter of the size of the control cabinet in central

installations, about 1 m wide instead of 4 to 5 m. Jansen: “And we can save an

average of 75% on cables. For the palletizer, we now only need 10 cables

instead of 40. This results in substantial savings in installation hours and

cable material, especially when it comes to shielded cables, also in context of

the electromagnetic compatibility.

Cooperation with SEW-EURODRIVE

The

cooperation with SEW-EURODRIVE dates back to the beginning. Jansen: “The first

machines we manufactured were equipped with SEW drives. SEW has proven itself

as a reliable partner due to the good service and active thinking about

solutions within our sector. Since Qimarox delivers worldwide, it is important

that a partner like SEW does the same and can support when needed."

Decentralized technology was not invented by SEW-EURODRIVE, but SEW, thanks to years of experience and extensive knowledge, has developed products that allow machine builders and manufacturers to make production lines ever faster and cheaper.

|

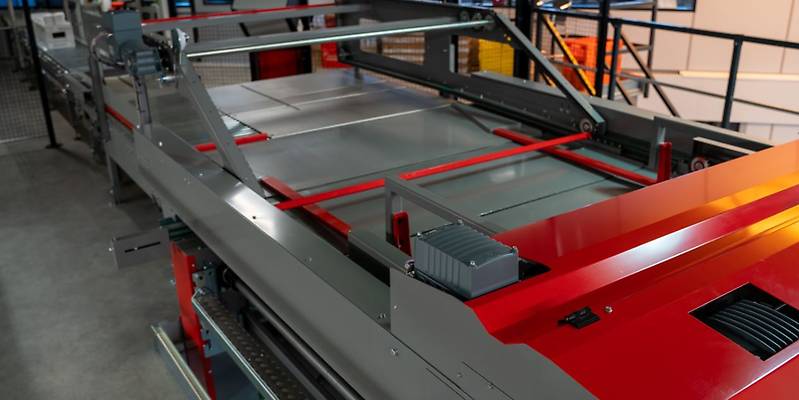

A well-known product is the Lowrunner LR3, a compact

palletizing cell that can handle a wide variety of products. Because of the

unique way of layer-forming - placing products in a layer - almost all patterns

can be made. The machine sets itself up fully automatically. Existing patterns

can also be modified through HMI (human-machine interface). But the user can

also create completely new patterns by simply entering the product dimensions

after which the software generates several patterns. The user chooses his

preferred pattern and the machine will then process the products according to

this pattern. All is done without the intervention of a programmer.

Ambitions

Qimarox has great ambitions. As the market leader, the company intends to continue its growth in the field of vertical conveyors and significantly increase its market share for palletizers.

\

\

Jansen: “We will also continue to work on broadening

our product portfolio. Key concepts are innovation, standardization, improvements

in width, more widely deployable machines, and capacity expansion to be able to

offer more added value, especially in intralogistics. Standardization ensures

quality for the user and makes our products available worldwide at the best

price. Cooperation with local integration partners ensures the desired

support."

Geen opmerkingen:

Een reactie posten